Steel is one of the most versatile materials when it comes to building and construction, contributing to its immense popularity, even in DIY projects. If you are working with steel on a building or construction project, an issue that is likely to arise is the joining of multiple steel sections and the best way of doing so. In this post, we compare two popular methods for joining steel, welding and bolting, to help you decide which is the better option for your needs.

Steel is one of the most versatile materials when it comes to building and construction, contributing to its immense popularity, even in DIY projects. If you are working with steel on a building or construction project, an issue that is likely to arise is the joining of multiple steel sections and the best way of doing so. In this post, we compare two popular methods for joining steel, welding and bolting, to help you decide which is the better option for your needs.

What is Welding?

Welding is a process of using high heat to melt and fuse two pieces of steel together. Because the steel is physically combined, this process is able to create a strong, permanent bond between two or more pieces of steel. There are also different welding techniques that can be used, allowing for varying degrees of precision and strength depending on the requirements of your project.

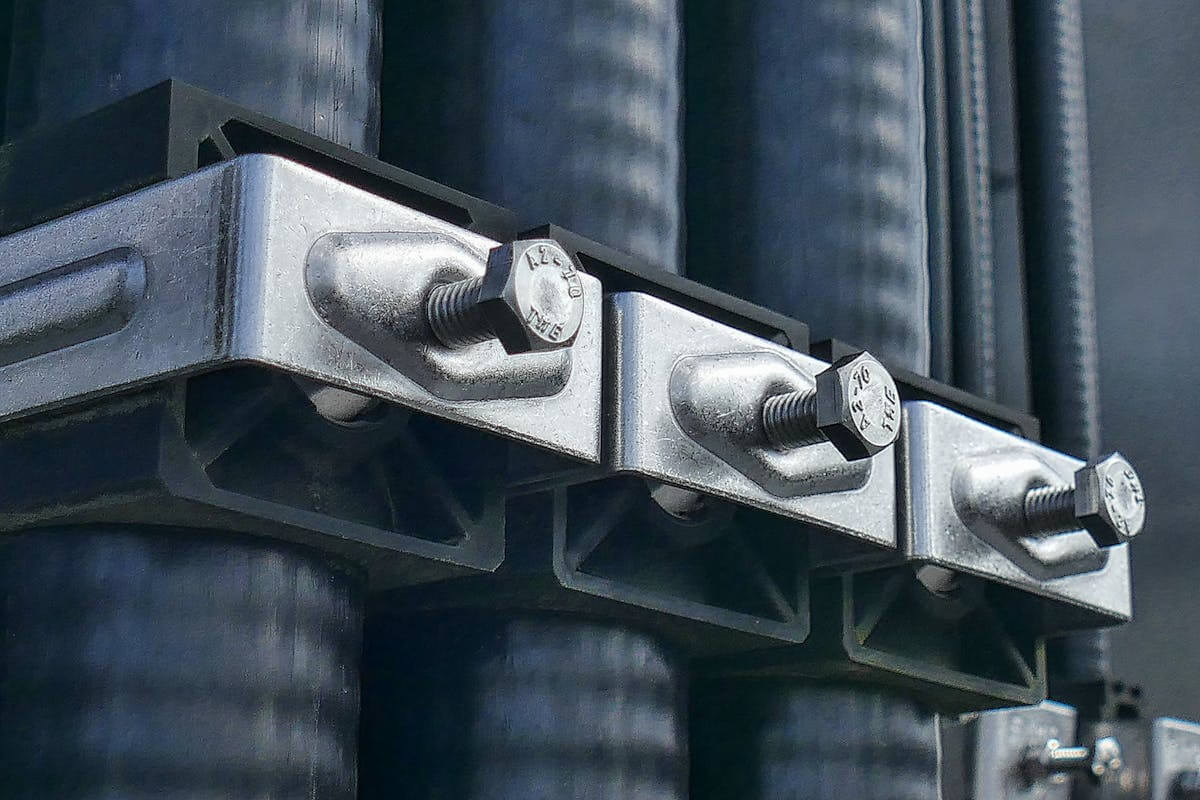

What is Bolting?

On the other hand, bolting is a much simpler process that entails joining two pieces of steel together using a bolt and a nut. Holes are first drilled into the steel components before a bolt is placed through the aligned holes and secured with a nut. Unlike welding, bolting does not require any specialised tools or knowledge beyond what is needed to drill holes in your steel components.

The Best Way to Join Steel in Your Project

There are pros and cons to both methods for joining steel and the best way to do so may not always be the same in all projects. Here are some of the key factors that may influence your decision in one way or another:

Time and Cost-Effectiveness

Compared to welding, bolting is a much more cost-effective way of joining steel. This is because bolting does not require the use of any specialised tools or equipment. At the same time, bolting it also a much faster process to perform, enabling you to save significant amounts of time.

Flexibility in Design and Construction

Because welding is generally permanent in nature, welded steel sections typically cannot be easily modified or repurposed for other uses or in cases where you might have a change of mind in terms of the design you are going for. On the other hand, bolts can be easily disassembled, thus allowing for greater flexibility in design and construction.

Strength Requirements

However, bolts may lack strength when it comes to applications that require higher load bearing capacities or exposure to intense stresses. In such cases, the higher strength that is imparted by welding might make welding the more preferable option for joining steel.

Get Your Steel from RW Steel

If you need steel for your next building or construction project, RW Steel has you covered. We are the number one supplier of steel in Melbourne and the surrounding areas and we offer a variety of steel sections for you to choose from, including galvanised steel posts, retaining wall steel and much more. Contact us today to find out more about how we can help with your steel needs.